PRODUCTS

Wafer Carrier

300mm Multiple Film Frame Shipper (25wafers store type)

Protos Carrier NDM-12M

12inch Film Frame Shipper (ESD Supported)

Achilles’ ND series can transfer your wafers both safely and efficiently. Since the wafer can be transported while it is attached to the tape frame, the time and effort required to put the wafer in the tray can be reduced.

Features

- Made from low particles/ionic/outgassing material

- Light weight when used with Protos Frames. *Sold separately

- ESD safe / Conforms to ANSI / ESD S541.

- Compatible with automatic wafer packing equipment.

Specifications

Related Items

- Interleaf

- Inner cushions

- Moisture barrier bags

How to store

12inch = 300mm wafer mounted on dicing frames / 25 wafers can be stored

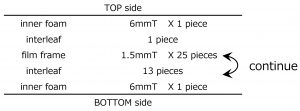

【Example :1.5mmT film frame】

*Inner foam thickness changes depending on the thickness of the wafer.

*This example does not guarantee that the wafer will not crack.

Cushion stacking guideline

Cushion stacking guideline

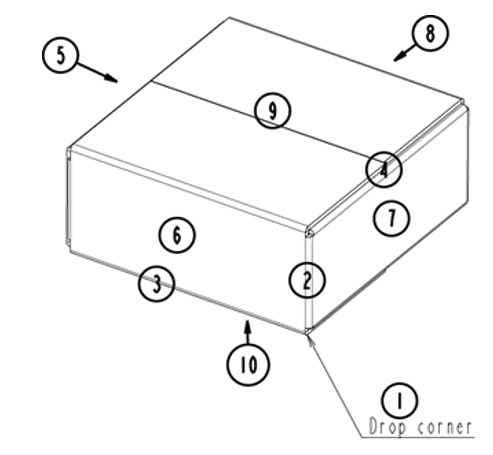

* Mark: ribs

Drop Test

Method

Dropped from a height of 100cm above the ground to the concrete floor.

| Item | Qty. | Part Number | Description |

|---|---|---|---|

| 1 | 1 | MA-16PEAS-6 | Cushion Ф400mmX6mmt |

| 2 | 25 | Si Wafer | Wafer, Ф300mmX0.775mmt |

| 3 | 25 | Frame | DISCO(DTF2-12) |

| 4 | 26 | PEA-15.5-350(Z1) | Interleaf, Ф395mmX0.35mmt |

| 5 | 1 | MA-16PEAS-6 | Cushion, Ф400mmX6mmt |

| 6 | 1 | Outer cushion | Styrene Foam |

| 7 | 1 | Carton | 510mmX510mmX200mm |

・Drop Direction: 10 directions (1 corner / 3 edges / 6 sides)

Result

| Drop Condition | Drop Condition | Result Wafer State |

|---|---|---|

| Drop Height: 100 cm Free fall to concrete floor ISO 2248:1985 Wafer Thickness:775 μm [N/W: 13.3 kg] [G/W: 15.7 kg] |

1 Corner | No cracking |

| 2 Edge | No cracking | |

| 3 Edge | No cracking | |

| 4 Edge | No cracking | |

| 5 Edge | No cracking | |

| 6 Edge | No cracking | |

| 7 Edge | No cracking | |

| 8 Edge | No cracking | |

| 9 Side(TOP) | No cracking | |

| 10 Side(BTM) | No cracking |

*Dropped from a height of 100cm above the ground to the concrete floor.

based on the evaluation method of ISO 2248:1985.

![ACHILLES CORPORATION [Achilles]](/asset/images/common/logo-achilles_en.svg)